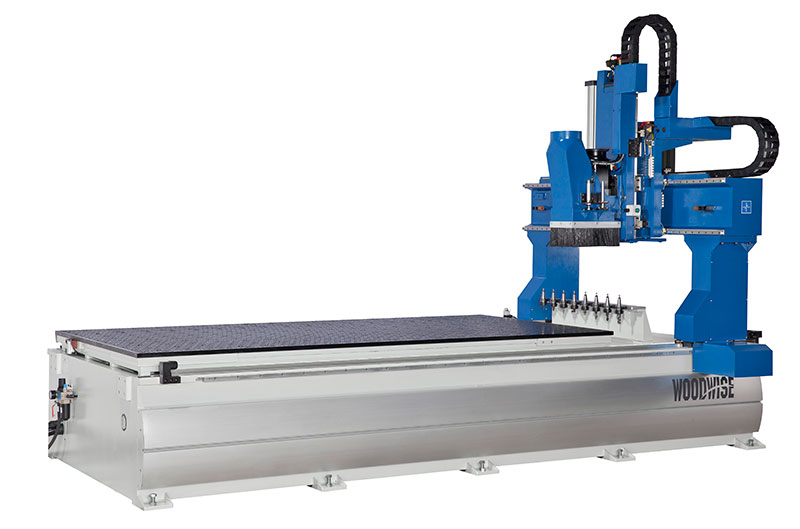

M Series

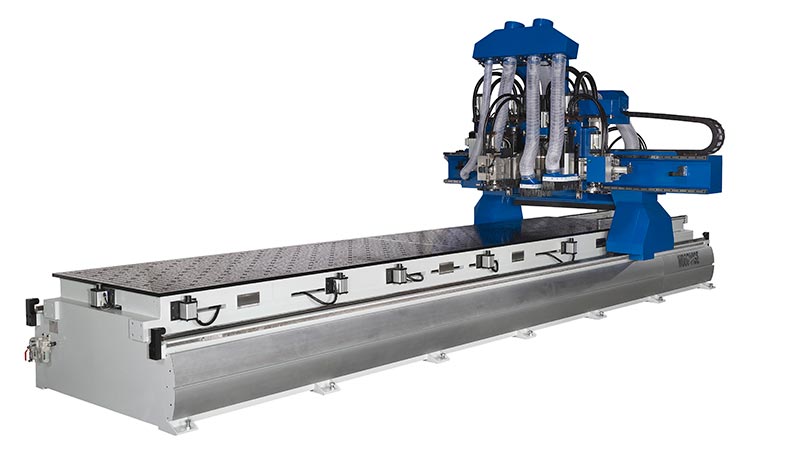

Moving gantry type CNC working center

Working travel X / Y / Z = 1800~9000 / 1220~2400 / 150~500 mm

Woodwise has been offering the most comprehensive range of moving gantry high-precision machining equipment for woodworking as well as nested based manufacturing applications, from the standard entry-level 8’*4’ model to the custom machines with over 14 meters of X-axis stroke and 3 meters of Y-axis for the most demanding high-efficiency machining operations.

Our nested-based manufacturing CNC machines are offered in one of the best in class Steel Frame Moving Gantry design with Two Synchronized Digital Servo-drive in X-axis direction which ensures the machining of precision engineering at high speed for a long service life; manifold types of tool changer with capacity up to 40-position and all can be customized via a full menu of our options.

- M 2050 / 5X

- M 1050 / 5X

- M 1050 / 5X

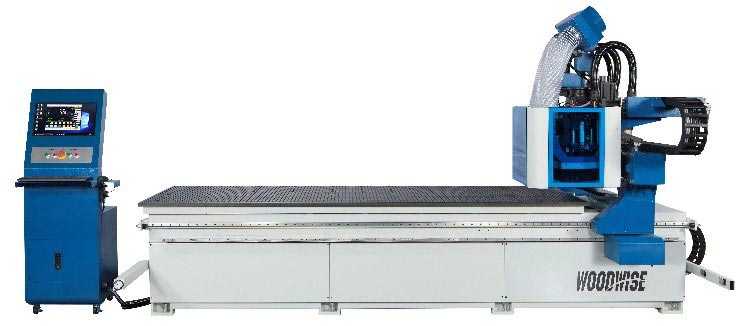

- MEC 361

- MEC 1040

- MEC 1050

- ME 361

- ME 1040

- ME 1050

- ME 1050 CE

- ME 1050

- ME 1070

- ME 1450 CE

- ME 2050

- ME 3080

- ME 1040 + Automatic loading / unloading system

- ME 1070 + Automatic loading / unloading system

- M 360

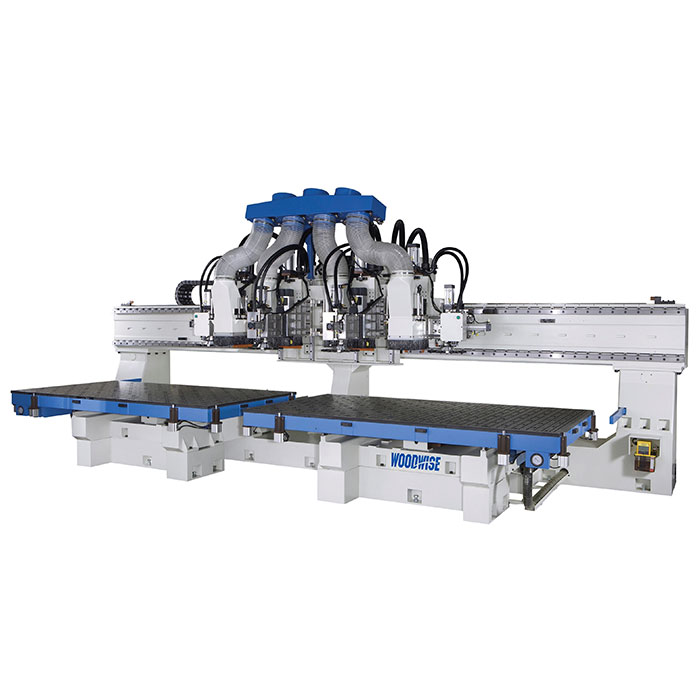

- M 2040/2

- M 1070 + Automatic loading / unloading system

- M 1260 + Automatic loading / unloading system/li>

- M 2040/2 + Automatic loading / unloading system

- Options

M 2050 / 5X

Working travel X/ Y/ Z = 6500 / 1500 / 600 mm

B / C = +/- 110゜/ 360゜

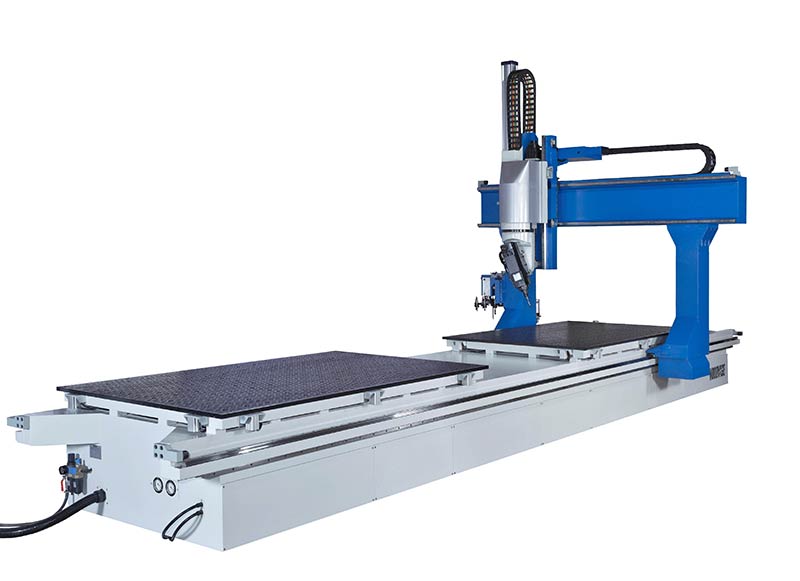

M 1050 / 5X

Working travel X / Y / Z = 3200 / 1500 / 450 mm

B / C = 40゜~-110゜ / 360゜

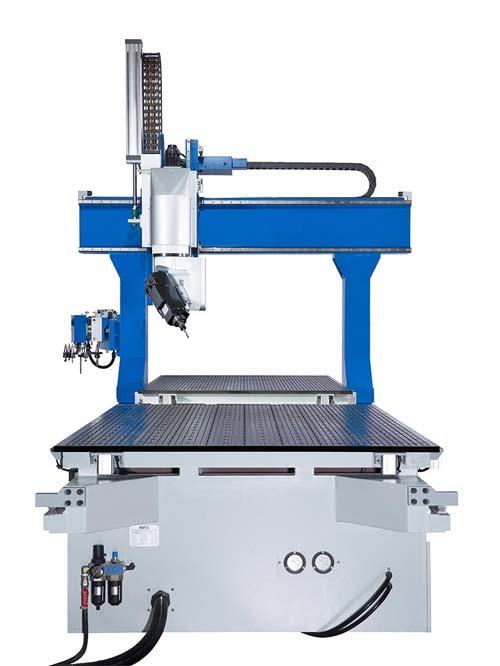

M 1050 / 5X

Working travel X / Y / Z = 3000 / 1500 / 500 mm

B / C = ±110゜ / 360゜

MEC 361 Working travel X / Y / Z = 2440 / 1220 / 150 mm

MEC 1040 Working travel X / Y / Z = 3050 / 1220 / 150 mm

MEC 1050 Working travel X / Y / Z = 3050 / 1500 / 150 mm

ME 361 Working travel X / Y / Z = 2440 / 1220 / 200 mm

ME 1040 Working travel X / Y / Z = 3050 / 1220 / 200 mm

ME 1050 Working travel X / Y / Z = 3000 / 1500 / 250 mm

ME 1050 CE Working travel X / Y / Z = 3000 / 1500 / 200 mm

ME 1050 Working travel X / Y / Z = 3050 / 1550 / 500 mm

ME 1070 Working travel X / Y / Z = 3050 / 2100 / 350 mm

ME 1450 CE Working travel X / Y / Z = 4200 / 1500 / 200 mm

ME 2050 Working travel X / Y / Z = 6000 / 1600 / 200 mm

ME 3080 Working travel X / Y / Z = 9000 / 2400 / 200 mm

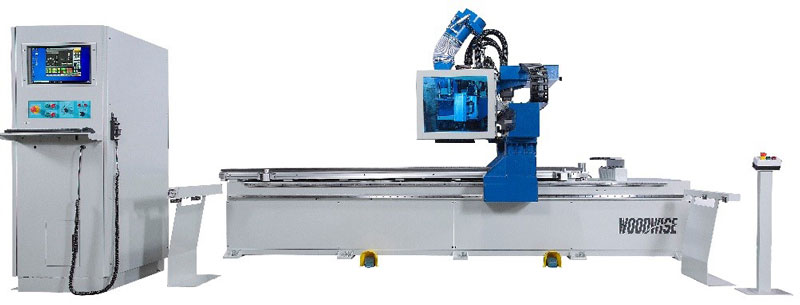

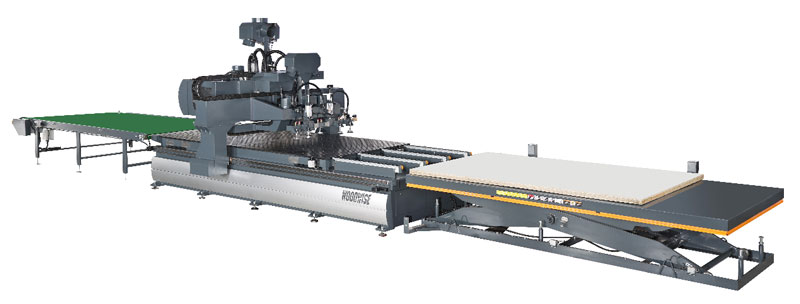

ME 1040 + Automatic loading / unloading system Working travel X / Y / Z = 3050 / 1220 / 200 mm

ME 1070 + Automatic loading / unloading system Working travel X / Y / Z = 3050 / 2100 / 200 mm

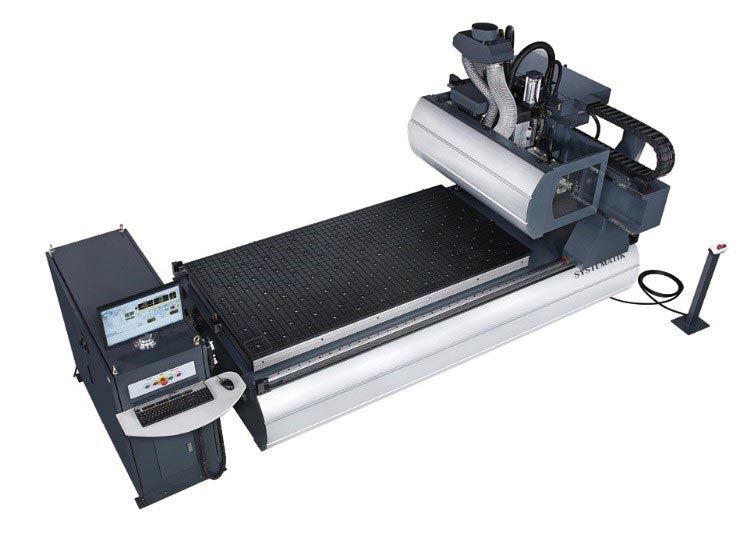

M 360 Working travel X / Y / Z = 2500 / 1250 / 250 mm

M 2040/2 Working travel X / Y / Z = 6000 / 1250 / 250 mm

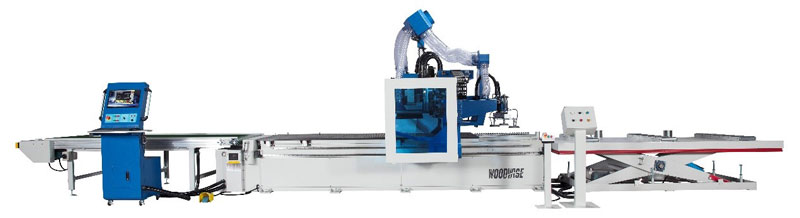

M 1070 + Automatic loading / unloading system Working travel X / Y / Z = 3200 / 2100 / 250 mm

M 1260 + Automatic loading / unloading system Working travel X / Y / Z = 3660 / 1850 / 250 mm

M 2040/2 + Automatic loading / unloading system Working travel X / Y / Z = 6000 / 1250 / 250 mm

Options

-

Lift table with rollers and fences for easy and correct positioning of panels

Lift table with rollers and fences for easy and correct positioning of panels

-

Loading device

Loading device

-

Pusher device

Pusher device

-

Automatic alignment system for accurate position loading

Automatic alignment system for accurate position loading

-

Auxiliary roller hold-down device

Auxiliary roller hold-down device

-

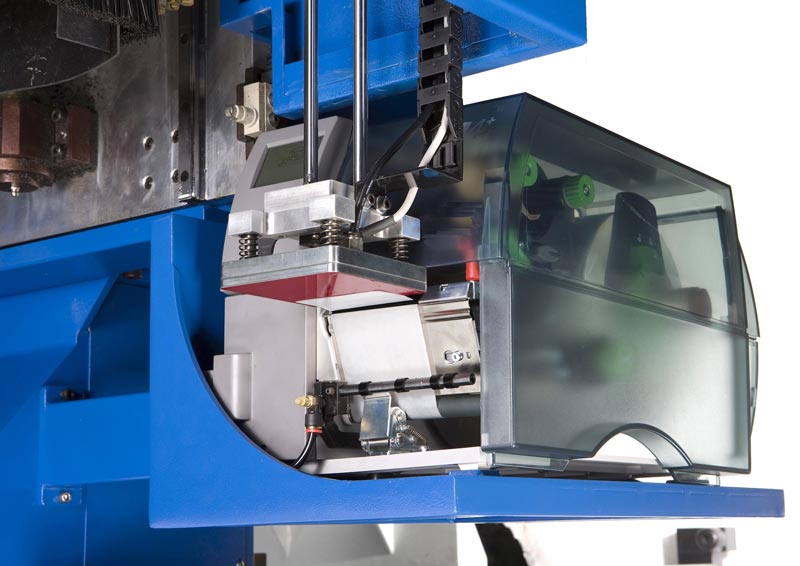

Embeded automatic labeling device

Embeded automatic labeling device

-

Automatic pre-labeling system

Automatic pre-labeling system

-

Automatic pre-labeling system with lift table

Automatic pre-labeling system with lift table